Industrial water reuse: the growing need to mitigate water scarcity

The increasing threat of drought is driving businesses across Europe and North America to reduce pressure on freshwater supplies by treating and reusing industrial water. By adding DESOTEC’s sustainable mobile activated carbon filtration solutions to existing wastewater treatment plants (WWTPs), companies are purifying their wastewater to the level required for reuse in industrial processes.

Water reuse: the context

In summer 2022, Europe experienced what is believed to be its worst drought in at least 500 years, with two-thirds of territory (EU+UK) under drought warnings or alerts.

High temperatures and low precipitation and snowpack have persisted in many regions across the world. Even in the winter and spring months of 2023/2024, drought was affecting areas including Spain and Sicily in Europe, Iowa and New Mexico in the USA, and British Columbia and Alberta in Canada.

In February 2024, Spain declared a state of emergency and imposed water restrictions in Catalonia after reservoir water levels dropped to below 16% of capacity. It began shipping drinking water from Valencia and Marseille, and announced a €467m investment in two desalination plants near Barcelona to treat 80m m³ of water annually.

As climate change worsens, it is forecast that global freshwater demand will outstrip supply by 40% by 2030. The pressure is on to reduce freshwater usage.

Why reuse water in industry?

Industry is a major global water stressor, using huge volumes in processes such as cleaning, cooling and rinsing.

In 2020, industry was responsible for 45% of freshwater withdrawals in the EU, 47% in the USA and 76% in Canada, against a global average of 15%. Within the EU, the figure rose to 81% in Belgium and 92% in Estonia.

Usually, wastewater is treated then discharged. However, investing in water reuse is becoming critical for many sectors for several reasons.

Most pressingly, it allows plants to continue operations during times of drought and restrictions, when drinking water supplies become prioritised for human consumption and pumping in nearby rivers is restricted. This ensures companies can continue to operate safely and at their usual standards of cleanliness, avoiding costly production downtime.

It also boosts circularity and sustainability, reducing the pressure on the local environment. This in turn improves a company’s reputation among neighbours and customers.

Furthermore, as legislation around industrial water usage may well be tightened in the coming years, a robust water reuse system is becoming an important future-proofing measure for many firms.

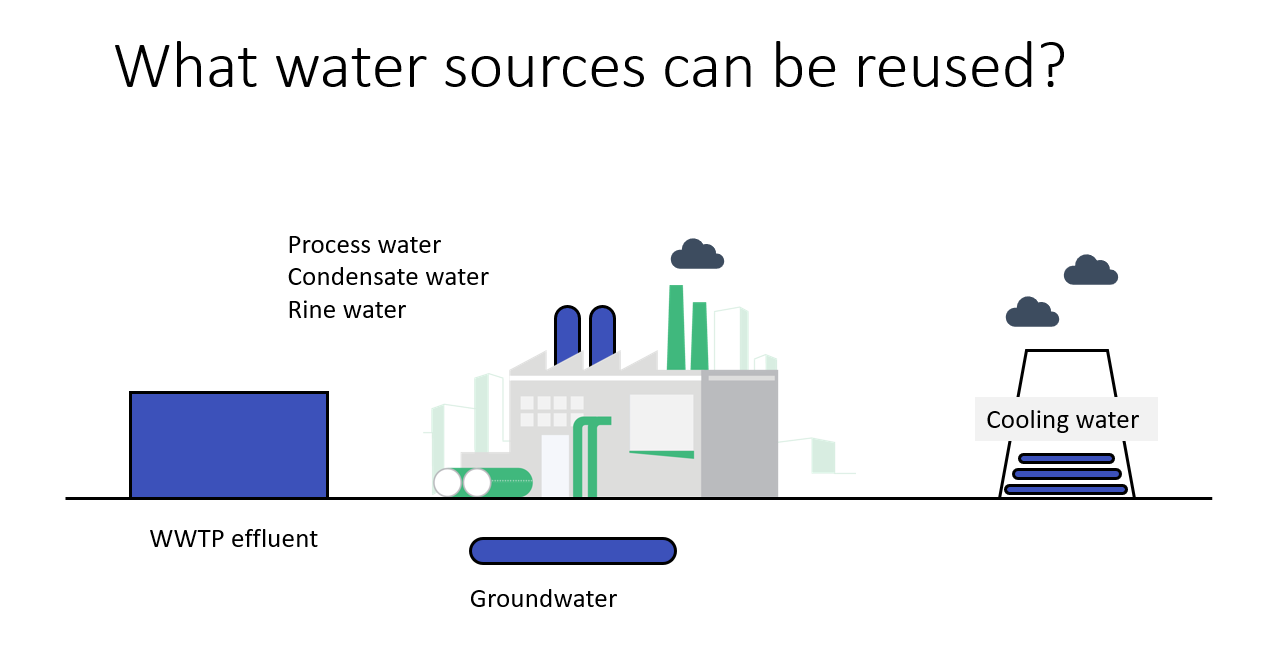

Water sources that can be reused after purification

Industries may be able to reuse treated water from sources including: WWTP effluent; industrial processes, condensation, cleaning and rinsing; cooling; and ground water.

The following impurities are typically found, and require treatment before the water can be reused:

- Process water: COD, BTEX, PAH, AOX

- Rinsing water: COD, detergents, soaps

- Cooling water: COD, residual oils

- Condensation water: Residual solvents

- WWTP effluent: COD, micropollutants

- Groundwater: COD, BTEX, PAH, AOX

Activated carbon technology, as used in DESOTEC’s sustainable mobile filtration solutions, is suitable to remove or reduce the above components: COD, BTEX, PAH, AOX, detergents, soaps, solvents, and micropollutants.

Where can reused water be used in industry?

Typically, the end-use of treated water is the same as its original source, e.g. process water is reused in industrial processes, and water from cooling reactors is recycled for the same use.

This ensures that the treated water is of the correct quality grade, and does not contaminate processes, equipment or products e.g. with fragrances, hydrocarbons or bacteria.

There is a wide range of potential uses, including: metal quenching; steam production; cooling reactors and/or effluents; wash facilities; stockpiles of extinguishing water; cleaning of vehicles and equipment; irrigating soil; and removing dust.

DESOTEC’s sustainable mobile filtration solutions for water reuse

DESOTEC provides sustainable mobile filtration solutions using activated carbon technology to several companies for water reuse projects.

Our solutions are mostly used as a polishing step after existing WWTPs. Sometimes, sand filters are placed before the filters to remove suspended solids.

DESOTEC mobile filters offer several advantages to customers:

- They are supplied on a rental basis with no need for upfront investment. This makes them ideal for temporary needs such as periods of drought, although many companies keep them in situ for the longer term.

- They are mobile so can be supplied within days from one of our hubs. They also start filtration immediately, suiting them to emergency situations.

- Our system is modular and adaptable to changing circumstances or unforeseen requirements. Filters may be simply added in parallel or series to handle increased flow rates or components.

- DESOTEC filters are easy to install and require minimal floorspace, so sites do not need to undergo major or costly changes to their facilities.

- They are simple to exchange in a process that takes just 30 minutes, minimising production downtime.

- Filtration waste is sustainably handled by DESOTEC away from customers’ sites. We transport closed filter units to our state-of-the-art facilities, where the saturated carbon is analysed and sorted. Components that were adsorbed onto the carbon are desorbed and destroyed in our furnaces, or valorised for reuse. Wherever possible, the carbon is then reactivated for reuse, driving down customers’ costs and improving sustainability.

Typical water reuse applications

Many industries, each with different treatment priorities, have installed water reuse systems including DESOTEC filters. As an example, these four sectors, which have high water demands, are particularly keen to find water treatment and reuse solutions:

- Paper industry. Treatment is required to reduce COD levels. If a reverse osmosis unit is present in the water treatment, activated carbon treatment may be placed upstream to protect the membranes, or downstream as a polishing step.

- Cosmetics and fragrance industry. Here, it is important to remove COD while preventing bacteria growth. High levels of purity are required, e.g. to ensure that reused cleaning water does not contain fragrance residue that would contaminate a new batch of a different odour.

- Chemical industry. Hydrocarbons must be removed from rinsing and process water before reuse. Purity levels depend on the processes for which the water is intended.

- Food and beverage industry. Cleaning water contaminated with cleaning products such as solvents can be reused after treatment, but high purity levels are especially important on food safety grounds.

Case studies

DESOTEC partners with clients in several sectors on water reuse projects. In all cases, the water is tested after treatment and found to meet the required purity standards for reuse.

1. Plastic industry

This Polish company recycles plastic granules and pellets, producing wastewater from washing, rinsing and cooling processes. The wastewater contains traces of food and cleaning products, with impurities including BTEX, PAH and mineral oils, measured as COD.

The company is keen to boost sustainability by reducing its usage of freshwater.

DESOTEC supplies a MOBICON 2000 filter to treat the flow of 5-15 m³/h, removing the organic impurities. It is preceded by other technology such as a WWTP including dissolved air flotation (DAF), and a sand filter to remove suspended solids.

After treatment and testing, the water is reused to rinse granules, closing the loop and helping the company achieve its green goals.

2. Metal industry

A metal company abstracts and treats canal water for use in its processes. During the summer, the canal water levels drop and the concentration of impurities rises such as COD, meaning the site’s WWTP is no longer adequate.

DESOTEC has placed a MOBICON filter downstream from the WWTP to provide an extra layer of treatment, removing residual COD. It treats a flow rate of 60m³/h.

The system enables the continuous production of process water without investment in major plant upgrades. It is also helping to protect the local environment by reducing stress on water courses.

3. Cellulose/ paper industry

This Spanish paper pulp manufacturer uses water from a nearby river in its processes. During the severe drought of 2023, it was unable to obtain water and had to stop production.

The company therefore decided to add an extra treatment step to its wastewater treatment plant so it could reuse its process water rather than simply discharge it.

DESOTEC placed three MOBICON filters in parallel, containing our ORGANOSORB 10 carbon grade. These remained in place for four months, enabling the manufacturer to resume production for the duration of the drought.

4. Food industry

A food company needs water to wash chickens on food safety grounds. Due to the high flow rates, it uses treated groundwater for this purpose. High purity levels are essential.

When the company detected the groundwater had become contaminated with pesticide, it faced the choice of stopping production, using drinking water, or finding a new purification solution.

DESOTEC supplied a MOBICON filter to treat the flow rate of 50m³/h so the water was safe for rinsing foodstuffs.

How can DESOTEC help you?

To discuss how DESOTEC can help purify your process water or waste water to reuse it, contact the team today.

Contact our expertsHow can DESOTEC help you?

To discuss how DESOTEC can help purify your process water or waste water to reuse it, contact the team today.

Contact our experts-

Water & liquid purification

Our mobile filtration solutions purify wastewater and groundwater, and ensure process liquids reach high purity standards. -

Our unique service

Our closed-loop, full-service model is as unique as your business needs. We’ll define the right filtration setup and safely recycle filtration waste, making it easy to go green. -

Your sustainability journey

We care about protecting our air, water and soil for future generations, just like you. Our filtration solutions help you meet environmental standards, reducing your carbon footprint.